옥외 광고 사업자에게 저전력 LED 전광판은 단순한 친환경 마케팅 슬로건이 아니라 수익에 직접적인 영향을 미치는 생존 문제입니다. 기존의 공통 양극 LED 스크린은 영업 이익의 최대 30%를 조용히 잠식해 왔지만, 차세대 에너지 효율 디스플레이 기술은 업계의 확실한 승부수로 떠오르고 있습니다.

운영비(OPEX) 절감 방안을 적극적으로 찾고 계신다면, 제대로 찾아오셨습니다.

14년의 제조 경험과 15,000㎡ 규모의 지능형 제조 기지를 보유한 국가 하이테크 기업인 소스트론은 수백 개의 글로벌 이벤트 제작 회사 및 국제 무역 고객과 협력해 왔습니다. 그 과정에서

고객들이 공통적으로 느끼는 문제점은 바로 초기 구매 가격보다 장기적인 전기 요금 부담과 과열로 인한 잦은 불량 화소 수리 비용이라는 점이었습니다.

4,000㎡ 규모의 연구개발 센터에서 측정한 데이터를 바탕으로 작성된 이 글은 공통 음극 기술이 제조 공정에서부터 어떻게 40~50%의 에너지 절감을 달성하는지 보여주고, 실질적인 재정적 수익을 명확하게 계산할 수 있도록 도와줍니다.

Table of Contents

ToggleWhat Is a Low Power Outdoor LED Billboard? (The Technical Core)

Before talking about cost savings, we must first understand the technical logic behind “energy efficiency.”

Most so-called “energy-saving LED screens” on the market ultimately come down to one key question:

Does it use Common Cathode Technology?

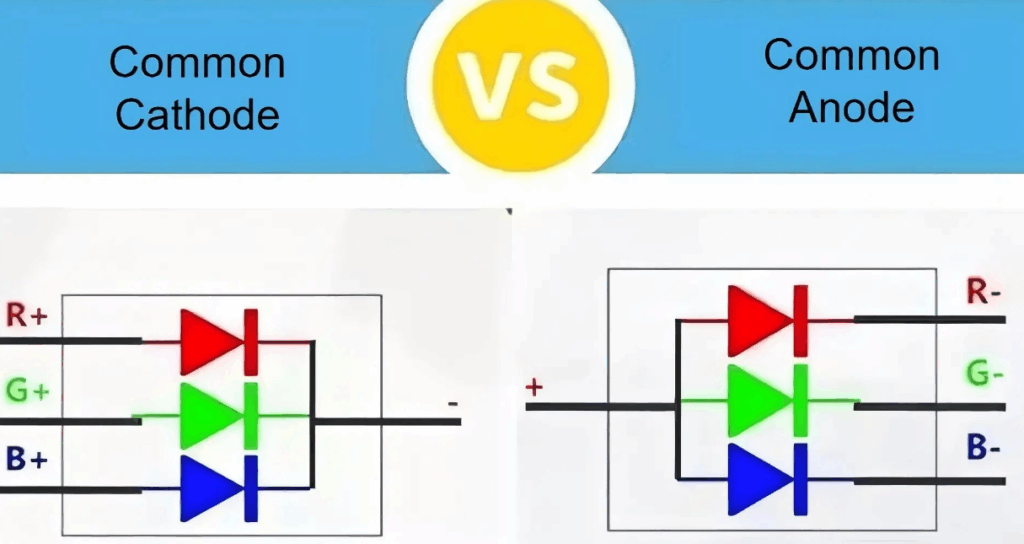

Traditional Common Anode Power Supply Explained

Most conventional outdoor LED displays use a common anode power supply. This approach is like flood irrigation—regardless of how much voltage red, green, or blue LEDs actually need, the power supply delivers a uniform 3.8V or even higher voltage to all of them.

The result?

Red LED chips, which only require about 2.8V, are forced to absorb excess power. That surplus energy doesn’t disappear—it turns directly into waste heat.

Sostron’s Solution: Precision Power Delivery

Sostron takes a precision drip irrigation approach.

Using our flagship ARES 2 Series as an example, it adopts an advanced common cathode architecture that precisely separates power delivery:

-

2.8V supplied directly to red LED chips

-

3.8V supplied to green and blue LED chips

No excess voltage.

No unnecessary heat generation.

Common Cathode vs. Common Anode: Three Critical Differences

To make the distinction crystal clear, here is a direct comparison:

| Key Metric | Traditional Common Anode Screen | Sostron Common Cathode Energy-Saving Screen | Your Benefit |

|---|---|---|---|

| Power Supply Method | Unified high-voltage supply; excess energy converted to heat | Independent R/G/B precision power delivery | 30%–50% energy savings, significantly lower electricity bills |

| Surface Temperature | Typically > 65°C (requires heavy air conditioning) | Reduced by ~20°C (typically < 45°C) | Saves on HVAC equipment and cooling costs |

| Color Performance | Long-term heat causes wavelength drift and color distortion | Low-temperature operation with stable color temperature | More accurate visuals, higher advertiser satisfaction |

Why “Low Power” Means a Longer Lifespan (Experience & Expertise)

Many procurement managers assume low power consumption is only about saving electricity.

Based on our manufacturing experience, the greatest hidden value of low power consumption is dramatically extending the screen’s service life.

Heat Is the #1 Killer of Electronic Components

For every 10°C increase in internal temperature, the failure rate of electronic components can double.

Thanks to common cathode cold-screen technology, combined with a full aluminum structural heat-dissipation design, the ARES 2 Series maintains stable temperatures without relying on high-speed internal fans.

This directly results in:

-

Slower brightness degradation – LEDs do not dim prematurely due to heat stress

-

Higher system stability – Power supplies and IC chips operate more reliably at lower temperatures

Real-World Case: Extreme Conditions in Southern France

In an outdoor project in southern France, a client installed a 6㎡ Ares Series P3.9 fixed outdoor LED display.

Challenge:

Intense summer sunlight and continuous exposure to high ambient temperatures.

Performance:

Thanks to the Ares Series’ 10,000 nits ultra-high brightness and common cathode energy-saving design, the display remains clearly visible under strong sunlight. Without installing additional heavy cooling systems, it has operated stably for over 3 years, with minimal brightness decay.

Conclusion:

This real-world deployment confirms our lab data—only by solving heat issues can you truly solve lifespan issues.

Real ROI Calculation: Let’s Do the Math (Authoritativeness)

For event company buyers and factory owners, purchasing decisions ultimately come down to the financial statements.

Many customers hesitate when they see that common cathode screens have a slightly higher upfront price.

However, according to financial data from long-term projects, once you calculate TCO (Total Cost of Ownership), the conclusion is very different.

A Realistic Commercial Scenario

Assume you install a 100㎡ outdoor LED billboard, operating 14 hours per day, with electricity priced at $0.20/kWh.

We compare a standard outdoor LED screen with Sostron’s ARES 2 Series (common cathode) over five years:

| Cost Category | Standard Outdoor LED (Common Anode) | Sostron ARES 2 Energy-Saving Screen | 5-Year Difference |

|---|---|---|---|

| Average Power Consumption | ~350 W/㎡ | ~180 W/㎡ | – |

| Daily Energy Use (100㎡) | 490 kWh | 252 kWh | 238 kWh saved per day |

| Annual Electricity Cost | $35,770 | $18,396 | $17,374 saved per year |

| Cooling / HVAC Cost | High-power AC running all day | Basic ventilation or small fans | ~$2,000 saved per year |

| Total 5-Year OPEX | > $188,850 | < $101,980 | > $86,000 saved over 5 years |

Numbers don’t lie.

In just about 1.5 years, electricity savings alone can offset the initial price premium. For the remaining 3.5 years or more, the screen is generating pure profit—not even counting reduced maintenance labor costs due to cooler operation.

Sostron’s Intelligent Manufacturing Advantage: More Than Just Energy Saving (Trust)

Why can Sostron achieve this level of efficiency?

Because low power consumption is not a single parameter—it is a complete system engineering approach.

4,000㎡ R&D Center Temperature Rise Testing

Every product labeled “low power” must pass extreme testing before mass production.

According to our internal lab standards, we simulate 60°C ambient temperatures (Middle East conditions) and ensure PCB surface temperature rise remains within safe limits at full load.

Structural Innovation: Storm Pro Die-Casting Process

Thermal performance is not only about circuitry—it’s also about structure.

Our high-end Storm Pro series replaces traditional steel cabinets with precision die-cast aluminum:

-

Steel cabinets: High heat retention, slow dissipation—like an oven

-

Die-cast aluminum: Excellent thermal conductivity with finned design for rapid heat transfer

This structural innovation allows lower energy consumption at the same brightness compared to competitors.

Deep Customization of Power Supplies and PCBs

As a national high-tech enterprise, Sostron does not use off-the-shelf power supplies.

We co-develop dual-channel output custom power supplies with top-tier manufacturers, specifically designed for our common cathode circuits—achieving over 90% power conversion efficiency.

Buyer’s Guide: Avoiding Pitfalls When Choosing Energy-Saving LED Screens

Many rebranding factories claim “energy saving” by simply lowering brightness. As a professional buyer, always verify the following:

Verify the Power Supply Method

Ask whether it is Common Cathode or Common Anode.

If the supplier cannot clearly explain voltage differences, consider that a red flag.

Request a Temperature Rise Report

Do not rely solely on spec sheets.

Request thermal images after 1 hour of operation. A true energy-saving screen should feel cool to the touch—often below body temperature.

Check the Brightness–Power Balance

Be cautious of screens claiming ultra-low power but only 3,000 nits brightness.

True technology (like the ARES Series) maintains 10,000 nits while reducing power consumption.

Inspect Protection Rating and Manufacturing Quality

Outdoor screens must withstand harsh environments. Confirm IP65/IP66 ratings and inspect potting quality—air bubbles reduce heat dissipation.

FAQ: Common Questions About Low Power LED Billboards

Q1: Does a common cathode energy-saving screen have lower brightness?

A: No. True common cathode technology (such as Sostron’s ARES Series) saves energy by optimizing power delivery—not by reducing brightness. In fact, lower heat improves LED efficiency, making 10,000 nits ultra-high brightness easily achievable.

Q2: If energy-saving screens save so much, why do people still buy common anode screens?

A: 주로 초기 예산 제약 때문입니다. 공통 음극 스크린은 맞춤형 구동 IC와 전원 공급 장치가 필요하기 때문에 초기 비용이 약 15%~20% 더 높습니다. 하지만 1년 이상 운영되는 프로젝트의 경우, 전기료와 유지 보수 비용이 더 많이 들기 때문에 공통 양극 스크린이 실제로 더 비쌉니다.

Q3: 기존 LED 스크린을 공통 음극 기술로 업그레이드할 수 있습니까?

A: 유감스럽게도 불가능합니다. 공통 음극 기술은 PCB 설계, 드라이버 IC 및 전력 아키텍처에 근본적인 변경이 필요합니다. 현재 사용 중인 화면의 전력 소모가 너무 크다면 Sostron Storm 시리즈 또는 ARES 시리즈 모듈이나 완제품 디스플레이와 같은 차세대 솔루션으로 점진적으로 교체하는 것을 권장합니다.

결론: 친환경적인 미래에 투자하고 숨겨진 비용을 없애세요

에너지 가격 변동성이 큰 시대에 저전력 옥외 LED 광고판을 선택하는 것은 더 이상 선택 사항이 아니라 비용 절감과 효율성 향상을 위한 필수 요소입니다.

Sostron은 ARES 2 시리즈의 공통 음극 혁신부터 Storm Pro의 구조적 열 방출에 이르기까지, 구매 비용은 물론 운영 비용까지 더욱 저렴하게 책정할 수 있는 디스플레이 솔루션을 제공합니다.

전기 요금이 광고 수익을 잠식하도록 내버려 두지 마세요.

운영 비용을 최적화할 준비가 되셨나요? 지금 바로 소스론 엔지니어링 팀에 문의하여 귀사의 프로젝트에 맞춘 무료 ROI 진단 보고서를 받아보세요.

참고 자료:

작성자: Dylan Lian

Sostron 마케팅 전략 총괄 디렉터